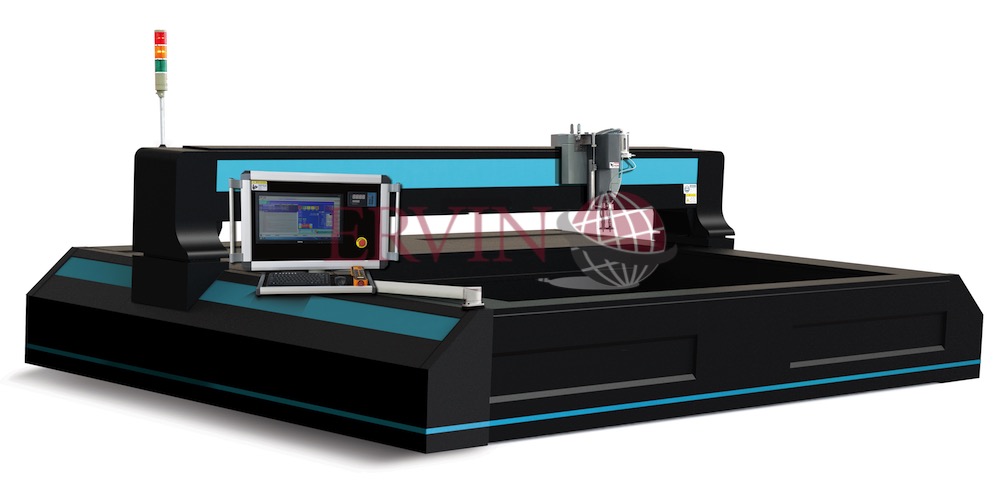

ERVIN Water Jet Machines:

Quality machines at an AFFORDABLE price, gives you the best value in the industry. Our heavy duty water jet machines are one of the most efficient ways to cut any type of material, especially glass, with no heat transfer. The machines are designed considering the long term working period, with very user friendly operations and all come with a 1 year warranty.

Main Features:

* Max. pressure: 380Mpa - 420Mpa

* Working pressure: 320Mpa - 360Mpa

* Continous working time: 24 hours

* Mechanical drive: Ball and screw and linear guide rail

* Controlling system: PC Controller/AC servo motor

* Cutting: X and Y direction

* Z axis travel distance: 150mm

Structural style:

Bridge style: Machine frame is seperate from the water tank. Suitable for cutting material with a wide range of sizes. Easy loading and unloading material from cutting bed.

* Cutting accuracy: +/- 0.10mm

* Accuracy of repeat positioning: +/- 0.05mm

Main technical data:

* Power supply: 220V or 480V 3phase 60hz

* Installed power: 25-40Kw

* Max. water flow: 3.0L/min - 3.7/Lmin

* Inner diameter of ruby orifice: 0.26mm - 0.30mm

* Inner diameter of mixing tube: 0.76mm - 1.00mm

* Water inlet pressure: 0.20Mpa

* Max. movement speed: 5000mm/min

High pressure pump:

* USA made parts (ceramic plug, high pressure cylinder, check valve, high pressure pipe, cutting head, high and low pressure seal kit, ect.) providing a maximum pressure of 380Mpa, working pressure of 320 Mpa (30 H.P.: 3,200 Bar, 45,000psi).

* USA made intersifier pump unit providing a maximum pressure of 420Mpa, working pressure of 380Mpa (50hp 3,800 Bar, 55,000psi)

Machine frame:

* X, Y, and Z axis machine frame

* Welded steel structure with tempering treatment to keep machine with in tight tolorances

* Precision ball screw, linear guide way, ensures stability and accuracy

* Integral metal plates covering and protecting the machine frame, ensuring accuracy and long service life

Water tank and cutting table:

* Water tank and cutting table are seperated from them machine for accuracy and stability

* Double layered water tank, 304 stainless steel material applied to the inside of machine

* Load bearing cutting table is arc-shaped, ensuring long service life

* Cutting table is adjustable for flatness

Controlling system:

* Servo motor and servo amplification

* PC system: Italian made ESA controlling system, which is reliable and easy to operate

* Coner slowdown, reverse cutting, and dynamic piercing auxilary functions

* Easy to adjust cutting speed to mee requirment of material

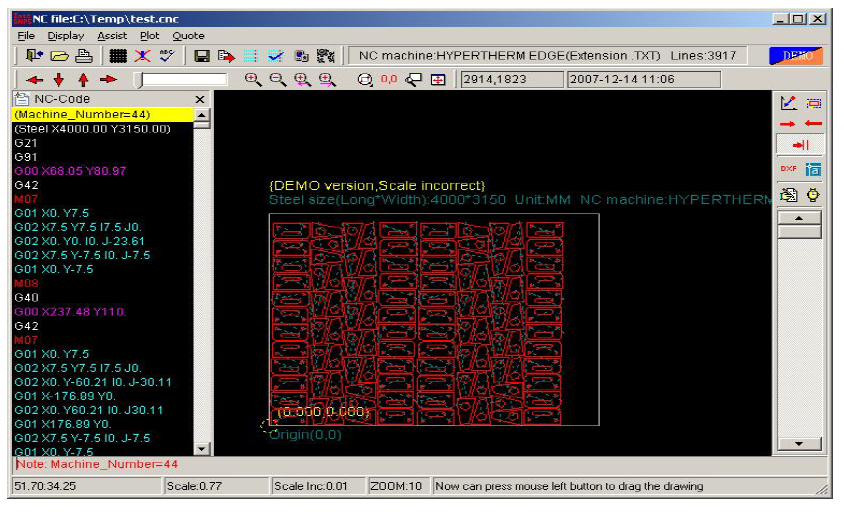

Programming software:

* PC configuration: Windows XP based, Intel 5300: 2G RAm: 320 GB HDD, 19" LCD Monitor

* Supports DXF file and auto programming to produce G-code

* U disk can be available to input file

* Functions: Auto-nesting, Auto programming, Auto kerf comensation, Edge-share cutting, Auto lead-in and lead-out, small ine segment auto-optimization fucntions, calculation of cutting perimeter

Automatic garnet supply system:

* Pneumatic type for eas of use

* Low garnet alarm

* Adjustable air cylinder can manually set the garnet flow

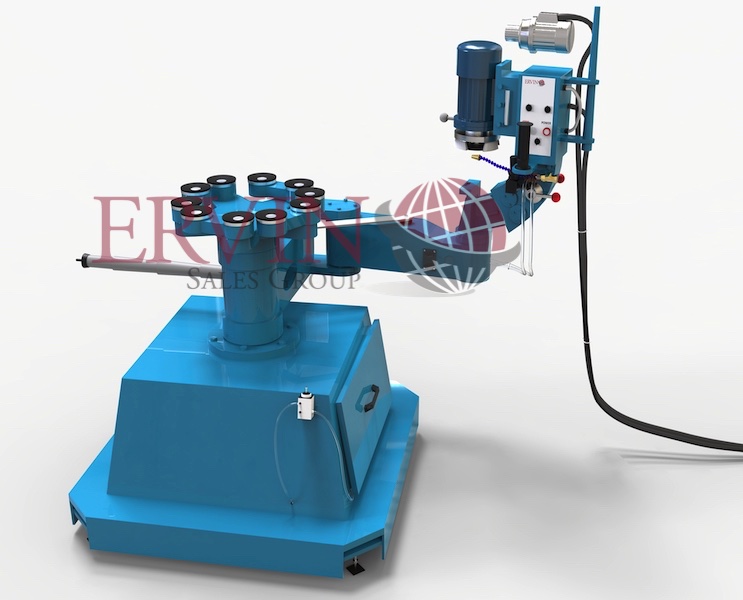

Cutting head assembly:

* Advance cutting head assembly which increases the cutting efficency, prolonging its life span

* Imported water on/off instantly by pneumatic valve and can be on/off according to the set time

Requirements:

* 220V or 480V power

* Water supply inlet at a pressure of 200Kpa

* Constanst dry air with a minumum of 800Kpa pressue

* 205 liters of super stabilized hydraulic oil

Options:

* Industrial cooler: the main function of the industrial cooler is to maintain the oil temperature under 40 degree which will greatly protect the intensifier system. The second function is to save water which could be circulated and utilized again

* Water softening system: good water condition is very important to the water jet cutting machine. Removal of hard minerals from normal tap water to soften can prolong the life of the high pressure parts to avoid scale formation

* Loading and unloading arms: to aid in lifting large items such as sheet of glass, metal or fragile itmes. Reduces the damage to materials and enhances worker safety

One of the most versitale cutting machines on the market.