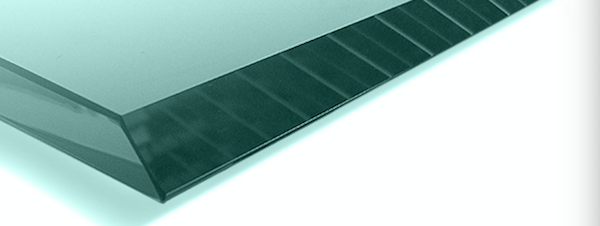

10 spindle Glass Edging/Miter machine

10 spindle Edging/Miter machine

10 spindle Edging/Miter machine

ERVIN Glass Edging and Miter Machines:

Quality machines at an AFFORDABLE price, gives you the best value in the industry. Our heavy duty glass edging and miter machines are suitable to polish all three faces of the edge of any glass or mirror products as well as perform a miter function up to 60*. The machines are designed considering the long term working period, with very user friendly operations and all come with a 1 year warranty.

Body Structure:

The machine body has been designed with a monolithic steel structure to guaranteed elevated levels of sturdiness and stability during the enitre life of the machine. Painted in multiple layers with a bottom coat of anti rust enhibitive paint to ensure a long service life.

* Depending on model there are different configurations in the wheel layout to suit desired application

* All machines utilize stainless steel water troughs along with rubber bellows for top performance in the wheel grinding areas

* Spindle slides are hardened steel plumbed for easy lubrication and are fully adjustable

* ABB German design spindle motors standard on all edging machines

Loading arms and racking:

Machines are equipped with an automatic loading/unloading arms consisting of high strength steel. They are run with heavy duty belts that will transport sheet weights up to 500lbs (chain driven machines) and 1,200lbs (roller bearing driven machines). The system allows for a very large array of sizes to be processed, even down to 30mm x 30mm on some modes.

* Standard length on entrance and exit conveyers is 3 meters (custom sizing is available to fit your required space)

* Machines come with both entrance and exit conveyor height adjustment (varries on models)

* All racking is aluimimun U channel with ball in track for ease of use and smooth operation

Electronics and PLC controls:

* Machines are equipped with top quality electrical parts for long lasting operation (Schneider, Mitsubishi, Omron, Siemens)

* PLC touch screen control available on all models of edging machines

* All machines are CE rated as standard

Water tanks and machine covers:

All machines come with 304 grade stainless steel water tanks as well as the conveyor convers. Being that these are some of the most corrosive and wet environments on the machines, the use of stainless steel ensures long service life and eliminates future issues.

Specifications:

* Running speed: 1.0 - 8.0m/min (depending on model)

* Power options: 220V or 480V 3phase 60hz (custom power options available)

* Miter function up to 60*

* Thickness range: 2mm - 25mm (up to 50mm+ on certian models)

* Minimum size: 80mm x 80mm ((down to 25mm x 25mm on certian models)

* German design ABB spindle motors standard on all edging machines

* Machines are set up as standard to run either felt wheel/wet cerium or cerium impregnated wheel

* Top quality electronics (Schieder, Seimens, Mitsubishi, Omron)

* 304 Stainless steel water tanks, water troughs, and conveyor covers

* Huge array of spare parts in stock to service customers (no down time)