PVB Glass Laminating machine (5 Layer)

PVB Glass Laminating machine (5 Layer)

PVB Glass Laminating machine (5 Layer)

ERVIN Laminating Machines:

Quality machines at an AFFORDABLE price, gives you the best value in the industry. Our heavy duty glass laminating machines are suitable to laminate both EVA and PVB films. The machines are designed considering the long term working period, with very user friendly operations and all come with a 1 year warranty.

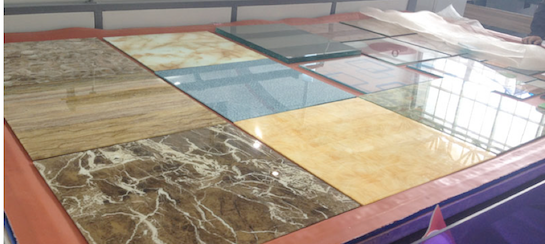

EVA laminating glass machine can produce laminated glass withou the use of and autoclave. The machine can work with silk, paper, plastic film, metal mesh, fiber mesh, switchable film and many other decorative film.

Heating Elements:

The heating elements are placed in a horizontal direction which is parallel to the glass surface. The heating is provided with electric radiant heat and is evenly distrubuted with the assisstance of 2 convection fans for very precise heating. This setup will quickly reach the target temperature, to save time and power consumption.

Main Cabin:

* The main body of the machine is made from high tensile steel to support large workload

* Able to produce single piece or multi piece per batch load (see different models)

* High quality tear resistant rubber bags with finger closure for leak proof seal

* Air assisted opening/closing main cabin door

* Insulated cabin walls to retain heat and shorten start up times

PLC control system:

All machines functions are controlled via PLC touch screen controls. All parameters can be easily set and adjusted for quick operation for many different types of applications. The PLC also controls the temperature which is regulated by means of adjusting voltage to the heating element, resulting in very accurate temperature control.

Specifications:

* Max glass size: 1800mm x 3000mm (custom size machines available)

* Vacuum bag size: 2000mm x 3200mm

* Max glass thickness: 19mm + 19mm

* Min glass thickness: 3mm + 3mm

* Machine dimension: 3500mm x 2260mm x 1200mm approx.

* Machine weight: 2 tons

* Floorspace required: 7300mm x 3780mm

* Power: 220V or 480V 3phase 60hz

* Heating temperature: 0* - 150*C

* Available glass: float glass, tempered glass, solorban glass, tinted glass, coated glass

* Cycle production time: 60 min.

* PLC touch screen control for easy operation

* Temperature is regulated by SCR for accuracy

* Independant control cabinet

* Vacuum bags are included with all machines

* Double working station for batch production

* All machines are CE rated